The quality of the final product in the industrial bakery and pastry sector is crucial for commercialization at such high production levels. To achieve this, it is essential to implement a quality control system that covers 100% of the production, without errors and with a speed that does not slow down the production pace. The best solution in terms of performance is clear: quality control by machine vision.

CHALLENGES OF INSPECTION IN INDUSTRIAL BAKERY AND PASTRY

In this section, we will discuss the challenges faced by industrial bakeries and pastry production. Then, we’ll explain how our machine vision inspection systems can solve these issues.

INDUSTRIAL BAKERY:

The biggest challenge in inspection within the industrial bakery sector is achieving the highest level of quality in 100% of the production. This requires controlling all visual parameters of the product at different stages. Additionally, there are often difficulties in the identification and correct classification of products, which can be attributed to various causes:

- The products are designed to have an artisanal finish, making them very different from each other.

- Metrological control of various parameters is necessary, depending on the product type.

- The subjectivity of certain parameters, such as the degree of toasting or the product’s shape, complicates quality control.

To overcome these barriers, we integrate vision and metrological control systems throughout all stages of the production process (mixing, shaping, fermenting, baking, freezing, etc.). Thus, quality control in bread production includes:

- 360º Control: Inspection of the top, bottom, and 3D aspects of the product.

- Application of specific metrics for each product type.

- Use of artificial intelligence to automatically classify products based on different visual parameters.

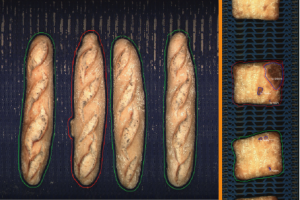

- Multiproduct lines: Accommodating different sizes and types of products (baguettes, loaves, ciabatta, etc.).

- Automatic rejection system for non-conforming products.

Cut detection in ciabatta bread using 3D vision with AI

INDUSTRIAL PASTRY:

Now we turn to the challenges of inspection in the industrial pastry sector. The primary challenge is the high production volume, which necessitates very fast quality control and, if desired, a high-speed rejection system. Another issue is the need for frequent deep cleaning, as these are fresh products with various fillings and decorations. This continuous cleaning requirement slows production and makes quality control even more difficult. The issues mentioned can be easily resolved with the integration of our vision-based inspection and quality control systems. This system, based on machine vision and AI, inspects products (e.g., chocolate-filled pastries) in real time as they move along the production line. This allows us to control the quality of all products at high production rates (>100,000 products/hour), while also checking the position and quantity of decoration using 2D vision and conducting dimensional control (width, length, height, volume) through 3D vision. To address accumulated dirt, our vision system is integrated with an automatic cleaning system for transportation and product rejection. This keeps the production line clean and safe, preventing cross-contamination and ensuring that dirt does not compromise product quality. It also optimizes the efficiency (OEE) of the machinery, as time and resources are not wasted maintaining the conveyor belt.

Decoration inspection and 3D metrology on a bakery line (>100,000 units/hour)

WHAT DOES OUR MACHINE VISION INSPECTION AND QUALITY CONTROL SYSTEM FOR THE BAKERY AND PASTRY SECTOR CONSIST OF?

Our machine vision quality control systems are among the most cost-effective solutions for businesses. Beyond their undeniable utility, several benefits arise from implementing them in inspection processes:

- Non-invasive quality control: Vision systems are minimally invasive, enabling clean and safer quality inspections.

- Elimination of subjectivity: All products follow the same quality standards, eliminating human subjectivity and enabling 100% objective quality control.

- Adaptability and flexibility: These systems can adapt to different products, whether on the same production line or across multiple lines. This means the same system can easily be adapted to work in another area.

- Optimal quality: Due to the minimal error margins of vision systems and their integrated rejection mechanisms, the final product quality perceived by customers surpasses other quality control methods.

- Quick return on investment: This technology can recoup the investment made in labor in a short period. Additionally, it significantly reduces the burden of quality control activities.

- Continuous operation: These machines can work constantly, optimizing production processes.

Many of our clients have also chosen to incorporate an automatic rejection system on the production line and/or a packing system at the end of the line. Both applications allow for optimal product quality and improved (and faster) automation of manufacturing processes.

THE ROLE OF MACHINE LEARNING IN VISION-BASED QUALITY CONTROL

Algoritmos de IA para el control de calidad

The advent of machine learning has enabled the adaptation of vision inspection systems to products with irregular shapes or morphologies, such as most bakery and pastry products (bread loaves, chocolate-filled pastries, croissants, etc.). Our systems are trained using neural network algorithms, making them capable of detecting defects in the product, as well as irregularities in its shape, filling, and decoration, without any human intervention. In addition to defect detection, deep learning enables our systems to detect the morphology, position, and dimensions of products, which also facilitates the integration of vision-guided robotics systems.

At Robotics & Vision Technologies, we bring cutting-edge technology to the industrial bakery and pastry sector, one of our areas of specialization. Contact us if you’re interested in incorporating a vision-based inspection and quality control system or if you want to learn more.. Vraia Corp