Machine vision is behind many significant advancements in industrial automation. One of the most notable achievements is its ability to automate quality control processes.

In many companies, quality control is still performed manually. However, while the human ability to visually inspect various objects is impressive, the subjectivity and fatigue resulting from repetitive tasks can lead to errors.

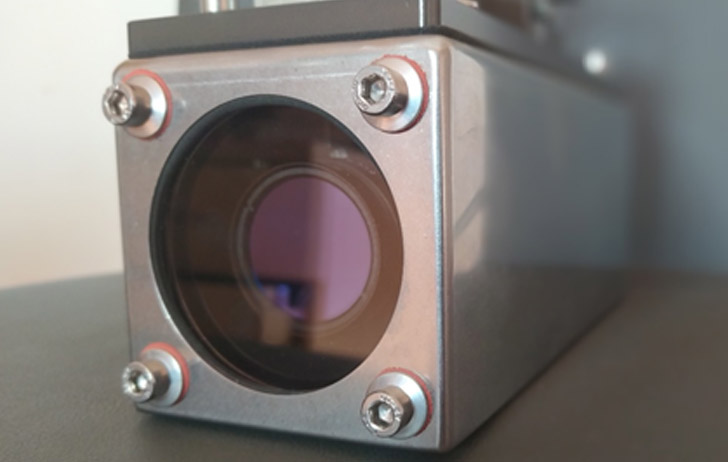

On the other hand, vision-based systems provide an effective method for quality control, adding value to inspection operations.

Benefits of Machine Vision for Quality Control:

- Elimination of Subjectivity in Human Inspection: These systems use consistent and quantifiable criteria that remain stable over time.

- Flexibility: Vision systems can adapt to the creation of new references and are scalable in terms of hardware. Thus, they offer a flexible technology that can adjust to production changes.

- Speed: Machine vision allows for the inspection of 100% of production, even in high-speed processes.

- Cost Reduction: These systems help reduce costs associated with quality control processes. By ensuring production quality, they prevent costs related to potential customer complaints/returns.

Machine vision has numerous applications for quality control, and it is a highly versatile technology with uses across various industrial sectors.

Some of the most common applications include surface defect detection, assembly verification, inspection of proper product sealing, label control, element counting, dimensional metrology, product type or quality level classification, and more.

Would you like to apply machine vision to one of your quality control processes? Contact us!