Technologies

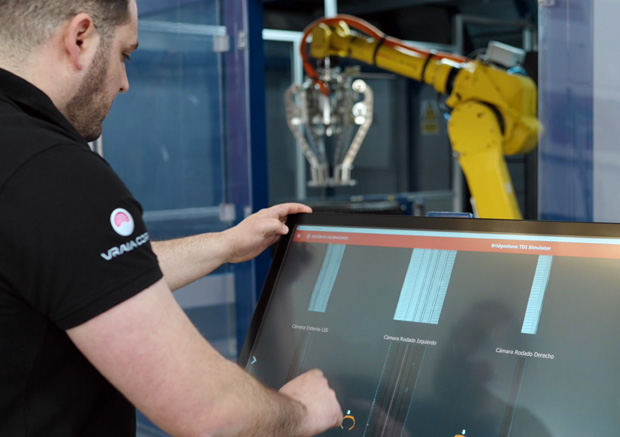

At VRAIA, we specialize in Industrial Artificial Vision and Robotics, developing advanced technology based on machine vision and augmented reality, while integrating artificial intelligence across all our systems.

Through the use of various image acquisition technologies, we equip our machines with industrial artificial vision to understand and interact with the complex industrial processes they manage, ensuring maximum precision and efficiency.

3D Vision | 2D Vision | Hyperspectral Vision | Thermal Vision

Applications:

• Quality control

• Dimensional control

• OCR and OCV (Optical Character Recognition)

• Surface inspection

• VGR (Vision-Guided Robotics)

Robotics

Our industrial robotics solutions focus on the design, construction, and operation of advanced robots in industrial settings. These systems perform tasks autonomously or semi-autonomously —such as assembly, welding, or packaging— often integrated with artificial vision and artificial intelligence to significantly increase efficiency and productivity in modern production lines.

Applications:

• Binpicking

• Palletizing

• Assembly

• Welding

• Painting

• Packaging

Artificial Intelligence

Our Artificial Intelligence integrated into industrial artificial vision systems significantly enhances a machine’s ability to ‘see’ and interpret its environment. By using advanced deep learning algorithms for precise object recognition and classification, we elevate the performance of vision-guided robotics (VGR) and automated quality control, ensuring peak efficiency in complex industrial applications.

Applications:

• Complex quality control

• Classification of subjective quality parameters

• Advanced object recognition and segmentation

• Anomaly detection

• Facial recognition

• Data analysis applications

Big data

Big Data refers to the analysis and processing of large volumes of data to extract valuable information and generate meaningful insights. In the context of machine vision in industrial environments, Big Data allows for the analysis and extraction of useful information from images captured by vision systems, improving quality, efficiency, and productivity in manufacturing processes, quality control, monitoring, and security.

Applications:

• Product quality improvement

• Preventive maintenance

• Increased machine OEE (Overall Equipment Effectiveness)

• Total traceability

• Optimization of manufacturing processes

• Industrial safety

• Waste reduction

Digital Twin

The digital twin is a virtual replica of a physical system, such as a machine or production line. It uses real-time data collected from sensors, vision systems, and other devices to simulate and optimize the performance, maintenance, and efficiency of machinery. It allows for virtual testing, failure prediction, and adjustments before implementing changes in the physical environment, reducing costs and downtime.

Applications:

• Machinery design optimization

• Deployment of new systems

• Workflow and new equipment simulations

• Production optimization